Micro-optics are extremely miniaturized optical components, with sizes ranging from about 200 micrometers to several millimeters. Past innovations in the micro-optics industry have led to a wide range of technologies that are commonplace in today’s economy, including non-invasive medical tools, cell phones, computer tablets, robotics equipment, sensors, and laser technologies.

Today, new micro-optics techniques push the limits of technology even further, being crucial to the development of 3D printers, biotech and genetic research, surgical imaging, dental applications, optometry and ophthalmology devices,, visual imaging devices, industrial engineering, and much more.

For both established and new applications, micro-optics systems most commonly require miniature, precision-engineered optical elements such as:

- Lenses & Lens Arrays

- Fiber Optics

- Prisms

- Filters

- Mirrors

- Mini-diffractive Optical Elements

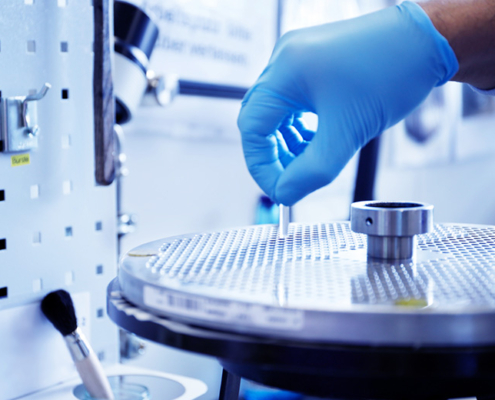

Although some micro-optics devices are fabricated in ways very similar to their larger counterparts, more intricate micro-optics designs instead require the continual development of completely novel material fabrication and handling techniques.

To do so, micro-optics technicians have borrowed precision-engineering methods from microelectronics and optoelectronics manufacturing, combined with conventional optics fabrication methods. Additionally, totally new methods must also be invented as micro-optics design and fabrication challenges arise. As a result, the micro-optics industry relies on continual advancements in manufacturing techniques to keep pace with the advent of new micro-optics products and applications.

The FISBA team works diligently with our customers to solve difficult optical design challenges as they arise, and our multi-domain knowledge allows us to fulfill even the most complex orders while meeting extremely tight timelines.