Applications of Micro-Optics Manufacturing

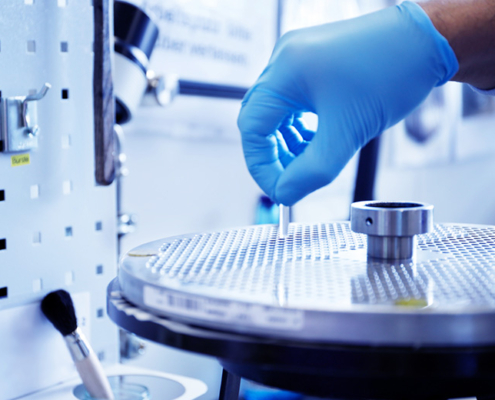

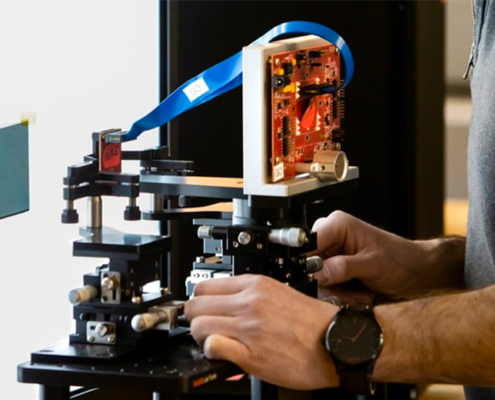

The miniaturization of optical components, known as micro optics, has revolutionized many industries. These tiny elements are driving innovation and performance in fields ranging from telecommunications to medical technology. Micro optics refers to lenses, mirrors, and other optical components that are typically less than a few millimeters in dimension. They manipulate light with high precision to improve the functionality of various systems. This blog will explore these microscopic marvels’ impact in laser systems, and medical imaging and diagnostics.