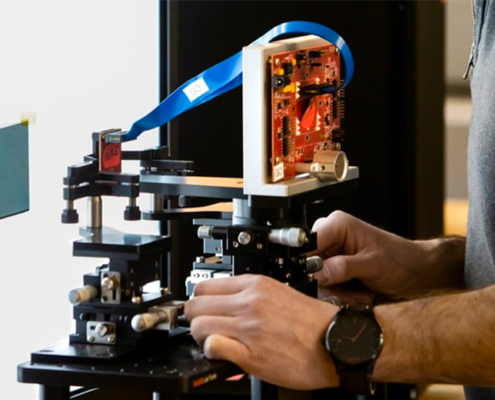

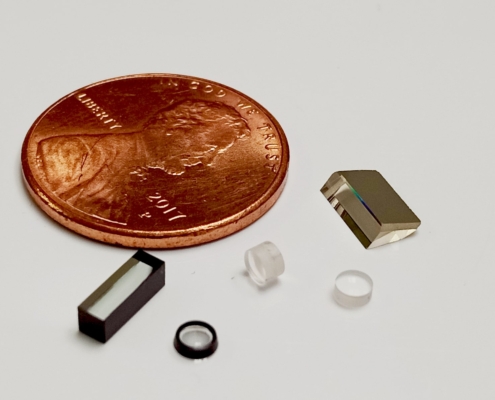

In the medical field, accurate and reliable imaging is vital. Optical assemblies play a significant role in numerous medical imaging applications. For example, endoscopes use various optical components like projection lenses, fiber bundles, and fused silica fiber bundles.

Other specialized lenses, such as fisheye or telecentric lenses, enable detailed examinations at both close and distant viewing fields, providing comprehensive visual information. As part of a well-aligned and calibrated optical assembly, these optical components can drastically improve the detail and reliability of medical imaging.

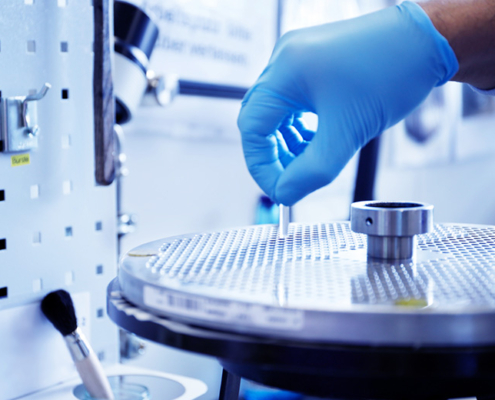

FISBA provides support and maintenance services, including repair, cleaning, and lens replacement for our assemblies. This equips your imaging systems for the long term without compromising efficiency and image quality.