This is particularly important to medical device companies where design to prototype challenges have become the norm; especially as companies seek to accelerate product launch cycles to capture a greater share of the market ahead of competition. R&D and engineering departments are challenged to keep up with ever changing product requirements, emerging technologies and resource limitations. When custom optics are required, there are very limited 3D printing equivalents available.

Recently a medical device client asked FISBA to provide a custom prototype assembly involving a challenging new lens design. With off-the-shelf (OTS) optics not an option, FISBA used its “design to the supply chain” model to achieve the client’s time frame. To learn more about the design to supply chain collaborative model, specialists are available at FISBA to provide helpful insights. Let’s walk through the major concepts in the design to supply chain model.

Communication

Clear communication is always a top priority in any design project. For time critical or accelerated projects, mistakes are magnified. Understanding and documenting what a successful outcome looks like with the client and supply chain is crucial. A clearly defined scope of work which identifies boundaries to limit scope creep; and allows for innovative thinking, will produce desired outcomes.

Identify Constraints and Resources

In early stage R&D projects, manufacturing and procurement constraints are often overlooked. This typically occurs when a product development process that supports verification on the design input from the manufacturing/operations group is not followed. Some examples of challenges that can be avoided include specifying difficult to acquire or restricted glass types, specifying tolerances outside known supplier manufacturing capabilities, and assigning specific components or work to vendors without first-hand knowledge of their capabilities.

Involving members from all areas of operations in the product design process, creates a more balanced approach of managing internal and external biases. Successful product design teams create a structure that identifies early stage risk and contributes know-how to solve challenges prior to reaching latter stages of the development process.

Application Domain Knowledge

At FISBA, a thorough understanding of the final product use and application nuances result in the ability to approach the design challenge fully prepared. As with most product designs, there are trade-offs to be considered related to product performance, features and medical device end use. Finding solutions to complex product development efforts, and developing prototypes fast, requires domain knowledge of the application that extends to engineering resources, skills and supply chain.

Putting it to Practice

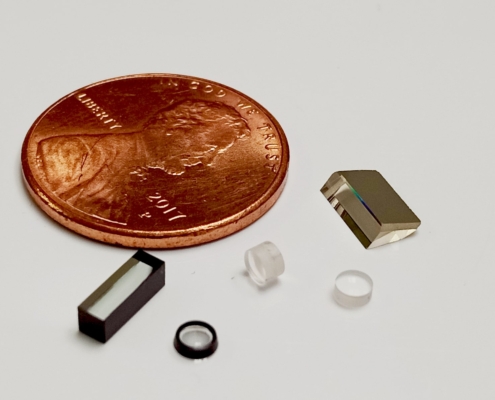

Using this process, FISBA completed a design prototype project in 6 weeks. Leveraging our supply chain, we delivered 20 custom lenses to our customer, enabling a critical product demonstration to their stakeholders.

Marketing departments will continue to identify new product opportunities that require time-sensitive engineering efforts for development. Engineering departments will continue to be challenged with resource and technology constraints. Working to a design process and mastering a design to supply chain model results in unique product development solutions.

Contact us here to learn more.